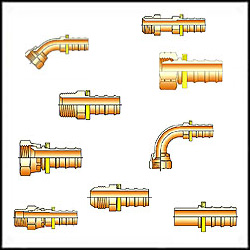

No-Crimp Hose Ends

Typical Application: Low pressure shop or service air lines. These hose pipe end connectors are often used for low pressure lube and oil lines.

Compatible Hose: NC hose both 250 & 300 psi.

Sizing: In 16ths as follows 02=1/8, 04=1/4, 06=3/8, 08=1/2, 10=5/8, 12=3/4 and 16=1

Pressure: Determined by maximum working pressure for hose size.

Material: Brass, steel, or stainless steel

Advantages: Easy to assemble – just push the fitting onto the hose. No clamps needed! Low cost and wide selection of configurations and sizes.

| Dash Size | Pressure | Sizing |

| -16S | 250-300psi | 2 |

| -02S | 250-300psi | 1/8 |

| -04S | 250-300psi | 1/4 |

| -06S | 250-300psi | 3/8 |

| -08S | 250-300psi | 1/2 |

| -16SS | 250-300psi | 2 |

| -02SS | 250-300psi | 1/8 |

| -04SS | 250-300psi | 1/4 |

| -06SS | 250-300psi | 3/8 |

| -08SS | 250-300psi | 1/2 |

| -16 | 250-300psi | 2 |

| -02 | 250-300psi | 1/8 |

| -04 | 250-300psi | 1/4 |

| -06 | 250-300psi | 3/8 |

| -08 | 250-300psi | 1/2 |

| -16B | 250-300psi | 2 |

| -02B | 250-300psi | 1/8 |

| -04B | 250-300psi | 1/4 |

| -06B | 250-300psi | 3/8 |

| -08B | 250-300psi | 1/2 |

Assembly Instructions for No-Crimp Hose Ends

- Identify over all length of hose assembly and allow for the cut off allowance for length of fitting(s) on these hose pipe end connectors.

- Properly measure and mark hose. Cut hose squarely with a cut-off tool or sharp knife.

- Lubricate the No-Crimp fitting, hose I.D., or both with light oil or soapy water only – DO NOT USE HEAVY OIL OR GREASE.

- Insert fitting into hose until first barb is in the hose.

- Place end fitting against a flat object such as a work bench or wall. Grip hose approximately one inch from end and push with a steady force until the end of the hose is covered by the yellow plastic cap.

Disassembly Instructions for No-Crimp Hose Ends

- Leave fitting in place, and cut hose approximately one inch lengthwise from the yellow plastic cap. IMPORTANT: Be careful not to nick barbs when cutting hose.

- Grip hose firmly and give it a sharp downward tug away from the fitting for disassembly.

Caution:

- Insert the No-Crimp fitting all the way into the No-Crimp hose until the cut end is concealed by the yellow plastic cap.

- Sealing integrity may be damaged by the use of exterior clamps.