Selecting Chemical Spray Hose

One of the most demanding hose application is chemical spray, as seen in lawn care and pest control. The hose is subject to both internal and external stress. Internal hose stress results from the high pressures used and the aggressive nature of the chemicals. External stress is applied to the hose by pulling and dragging the hose, as well as exposure to the freshly applied chemicals.

In order to obtain optimum performance and service life, it is essential that the proper hose be selected and that proper care be taken in handling the hose.

What Type of Chemical is being Conveyed?

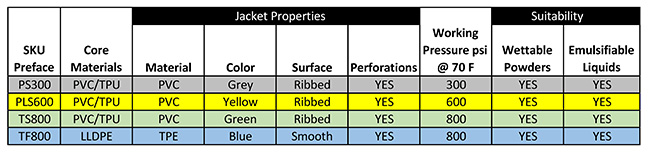

In general, lawn care and pest control chemicals fall into two classifications, based on the physical form of the substance: Wettable Powders and Emulsifiable Liquid Concentrates.

Wettable Powders are supplied in dry powder or granular form and are dissolved in water to create a sprayable solution. The substances are generally stable when in solution and will not settle out when allowed to stand. All of our pest control, lawn and tree chemical spray hoses will handle most of the wettable concentrates in aqueous solutions at normal suggested concentrations.

Emulsifiable concentrates are supplied in a liquid form in which the herbicide or pesticide is dissolved in a carrier that is itself a solvent or oil-based substance. When mixed with water, these substances become emulsions in which the chemicals are not truly dissolved in the water. When allowed to stand, the chemicals will separate from the water, generally floating to the top. The emulsified carriers themselves have an effect on the hose’s core tube and, in combination with the other chemicals being used, can have a significant effect on the hose material when they separate and form a more concentrated phase.

For emulsifiable concentrated chemicals, we suggest using PVC/Polyurethane blend compounds in the core tubes, such as PS300, PLS600, TS800 and TF800.

Regardless of the type of hose used with the emulsifiable concentrate chemicals, it is recommended that the hose be drained if it is going to stand for an extended period of time, since even on a reel the chemicals may separate out of the water emulsion and collect in concentrated bands at the top of the reel.

For transfer of an emulsifiable concentrate in its pure form, a premium chemical spray hose such as TF800, with its polyethylene liner is suggested.

At What Working Pressure and Operating Temperature will the Hose be Used?

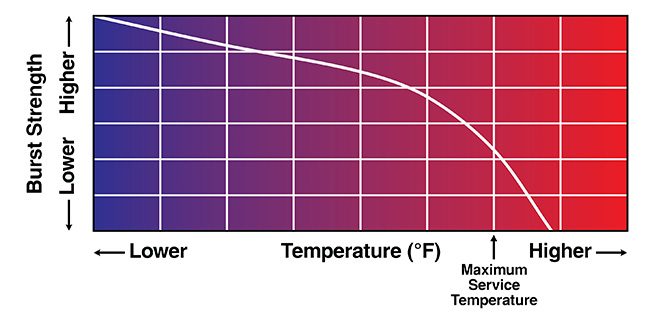

All hoses, but particularly thermoplastic hoses, are affected by temperature. As the operating temperature rises, the material will soften slightly and the working and burst pressures will be reduced. It is not unusual for the hose temperature in a lawn spraying application to rise to 120°F in summer. The individual pressure rating tables should be consulted to determine the maximum working pressure at 122°F.

In general, one can expect a reduction of 40% to 60% in working pressure rating at 120°F, when compared to the working pressures for the same hose at 70°F. This factor must be considered when selecting the proper hose.

Reprinted From Kuriyama Kuri Tec KKTCA0408