Hose Barb Suggestions for Low Pressure Hose & Tubing

It is extremely important that the fitting and hose or tubing be properly matched in size and type. The insert should always be slightly larger than the tubing to create a slight expansion of the tube and provide a good consistent seal. If a clamp or ferrule is used to compress the hose, caution must be used to prevent over-crimping the clamp or over-tightening the ferrule. More pressure does not necessarily improve fitting retention.

We do not recommend the use of reusable fittings unless the hose and fitting have been specifically designed to be compatible and have been thoroughly tested in combination prior to use.

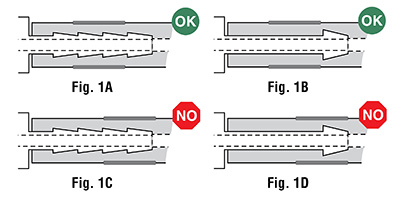

Clamps Over Barbed Fittings

In the illustrations, the clamps are properly positioned in Figures 1A & 1B, directly over the middle barbs and behind the first barb. This is extremely important in the case of single-barb fittings, as shown in Figure 1B, since the barb is generally much larger than the shank of the fitting. The compressed material cannot pass over the barb when under tension, thus securely holding the fitting to the hose.

fittings, as shown in Figure 1B, since the barb is generally much larger than the shank of the fitting. The compressed material cannot pass over the barb when under tension, thus securely holding the fitting to the hose.

In Figures 1C & 1D, the clamp has been improperly positioned too close to the end of the fitting. In Figure 1C, only the barb nearest the end of the fitting is effective in maintaining fitting retention. The first two barbs serve no purpose whatsoever in providing fitting retention or leak resistance. In Figure 1D, the situation is even worse, since the clamp can very easily cut the core tube over the enlarged barb, leading to leakage and subsequent cover blisters or bursts.

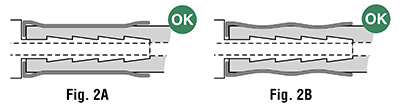

Ferrules Crimped Over Barbed Fittings

When properly crimped, a metal ferrule over a multi-barbed fitting can provide excellent fitting retention and leak resistance. However, excessive crimping pressure can damage the core tube, leading to hose failure.

In Figures 2A & 2B, the two styles of crimping die have been used successfully. The ferrules and fittings are properly matched in length.

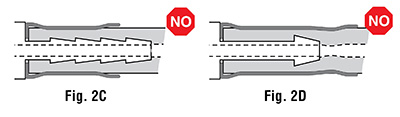

In Figure 2C, the ferrule is much shorter than the barbed insert. Without the protection of the ferrule, repeated harsh flexing of the  hose at the fitting can damage the tube. In addition, the short ferrule does not take full advantage of the sealing or retention properties of the barbed insert.

hose at the fitting can damage the tube. In addition, the short ferrule does not take full advantage of the sealing or retention properties of the barbed insert.

In Figure 2D, there are two potential problems: 1) The excessively long ferrule can reduce the inside diameter of the hose just beyond the fitting; and 2) a single barb fitting is not the ideal insert for a crimped ferrule. Because of the increased depth of the single barb, the tube can be cut by the force of the crimping before sufficient compression is exerted on the shank of the fitting.

Hose Failure Near A Fitting

A hose is most susceptible to failure near the fitting. The installation of the fitting involves some risk of damage to the core tube. There is also some possibility of slight leakage along a fitting and subsequent yarn wicking, particularly if a one piece crimped fitting is used. The greatest amount of flexing often occurs near the fitting at either the supply or service end of the hose.

In the investigation of a hose failure near the fitting, it is essential that the fitting / hose interface be examined. In the field, if the failure or deterioration is isolated to the area near the fitting, it is best to cut off the end of the hose, reinstall a new fitting and monitor the hose in service to see if the problem reoccurs.

If the problem involves a spray hose and fluid slowly leaking through the cover perforations near the fitting, the most likely cause is wicking along the reinforcing yarn from the end of the hose or from a cut or break in the core tube.

Such wicking can extend over several feet and a leak may be seen at a considerable distance from the source of the leak.

Warning

The above comments and fitting suggestions are intended for use as guidelines only. The information provided is based on tests which we believe to be reliable and on our past observations and experience. No Warranty is expressed or implied, as applications and methods of fitting installation can vary widely. Before placing a hose in service, the user must determine the suitability of the fitting and hose / tube for his or her intended use. The user assumes all risks and liability resulting from the use of any HoseandFittings.com product with any fitting whatsoever.

Reprinted from Kuriyama KuriTec Catalog KKTCA0408